DEFEND AGAINST THE ELEMENTS

Corrosion attacks both the inside and outside of your outboard—every day, all the time—even if you’re boating in freshwater. Ensure optimal performance, reliability, and longevity by staying on top of your corrosion mitigation. Your dealer can provide corrosion preventatives but using them regularly is entirely on you. Let’s go over the products and procedures you can use to protect your engine.

CHOOSE YAMALUBE®

This mild, biodegradable detergent can be used to clean outboard exteriors.

Yamalube oils, cleansers, sprays, sacrificial anodes, and fuel additives are specifically formulated to provide lasting protection and gently remove various types of marine corrosion caused by freshwater, saltwater, ethanol fuels, contaminants in water, and more.

Dry corrosion. This is corrosion from the inside out and occurs in areas not in direct contact with water—exhaust systems, for example. The outsides of most exhaust systems are cooled by raw water to prevent overheating. When today’s ethanol-enhanced fuel is burned, it creates by-products known as sulfate salts. These salts are highly corrosive, especially when exposed to very hot temperatures.

If the outboard’s cooling water passages are not kept clean by regular flushing, hot spots can form on the interior of the exhaust components, concentrating the sulfate salts’ corrosive effects. Flushing your engine with fresh, clean water for 15 minutes after each trip is a vital part of preventing even dry corrosion.

Exterior corrosion. This can occur everywhere from the external powerhead surfaces to the propeller. Set up a regular corrosion inspection and treatment schedule, washing and treating surfaces to remove corrosion and prevent it in the future.

DO IT YOURSELF

Saltwater is naturally corrosive and any remaining inside after use is left there to do its worst. Saltwater can also crystallize when exposed to heat above 170 degrees, which causes deposits to form, potentially restricting cooling water passages. It’s a must that you flush your engine thoroughly with fresh, clean water after every use.

Connect a garden hose to the inlet side of your non-running outboard’s flush attachment, turn the spigot on full blast, and let the hose’s water pressure do the work. Let the water run for 15 minutes to ensure it fully circulates through the entire cooling system several times. If your boat’s out of the water, the fresh water will trickle down and clean the water pump and the lower unit’s cooling water passages.

After removing the top cowling and propeller, connect a garden hose to clean fresh water on one end and a “flush muff” attachment, which slides around the lower unit to provide water to both sides of the raw water inlet, to the other end. Turn on the hose until you see water squirting out the sides of the muff, then start your outboard in neutral. Operate the engine at idle RPM only and allow to run for 15 minutes. Increase hose water pressure enough to maintain a bit of squirting out from under the flush muffs at all times. This helps ensure it gets fed enough cooling water.

NOTE: Outboards utilizing two cooling water inlets require a special adapter to use this method. Check with your local authorized Yamaha Outboard dealer.

NOTE: Only operate engine at idle RPM while flushing.

WARNING! For safety, remove the propeller before you begin. Accidental engagement of the outboard into gear with the outboard running will cause an exposed propeller to spin rapidly, possibly resulting in serious injury or death.

Place the bag around the outboard, attach the hose, and fill the bag. Ensure the water level reaches the height of the outboard’s water pump (about 1” above the lower unit separation seam). Start the engine, and run for 15 minutes in neutral. Leave the hose running during this entire procedure. When complete, stop the outboard, then the hose, and then drain the bag.

NOTE: Thoroughly dry the bag before storage.

Rinse it. When returning from a trip, rinse the entire outside of the outboard with clean water. Give it a once over with some mild soap like Yamaclean® Pro-Wash Spray and a soft cloth (do not use liquid dish detergent). Wash the whole boat and trailer, wiping it down with a quality chamois afterward.

NOTE: If salt build-up has become a problem, or your outboard’s powerhead has been directly in contact with saltwater, it’s okay to gently rinse portions of the powerhead with clean, fresh water to remove salt, etc. Use a hose on low pressure—not a spray attachment—and don’t rinse around the air intake area. Rinse out the inside of the cowling, too. Make sure both the powerhead and the cowling are completely air-dry before reinstalling the cowling.Spray it. Yamashield is a lubricant, a water displacement agent, and a corrosion preventative all rolled into one. Spray all external powerhead surfaces and the electrical connections to help keep them corrosion-free.

Check it. Do a visual inspection of your boat and Yamaha outboard(s) every time you use them. Look for anything out of the ordinary and investigate. Keep a special eye on anodes. Anodes intentionally corrode before your outboard does, to help protect it. Better known as “sacrificial anodes,” they are typically dull gray in color. On Yamaha outboards, they’re usually located on the lower unit just above the prop and on the bottom of the engine bracket. As corrosion occurs over time, they begin to “dissolve.” Replace them when they are about 50% gone with only high-quality, factory-recommended replacements. Yamaha sacrificial anodes are made of a blend of high-quality alloys specifically designed to help protect your outboard.

NOTICE: Never paint or cover anodes, as they must be in direct contact with the water in order to perform correctly. When exposed to the water (especially freshwater), they can become covered with a layer of organic growth (often referred to as “scum”). This is often so thin you won’t even notice it, but it can prevent an anode from doing its job. During your regular washdown procedure, take a brush and some soap to the anodes to keep them clean and in direct contact with the water.

If corrosion appears, it’s time for Yamalube® Battery Terminal Cleaner & Protector. Spray it on to clean the affected areas (heavily corroded connections will first need to be disconnected and thoroughly cleaned). Then rinse it off with water, to leave behind a residual protective film on terminals that helps keep corrosion from re-forming.

HAVE YOU INSPECTED FOR CORROSION RECENTLY?

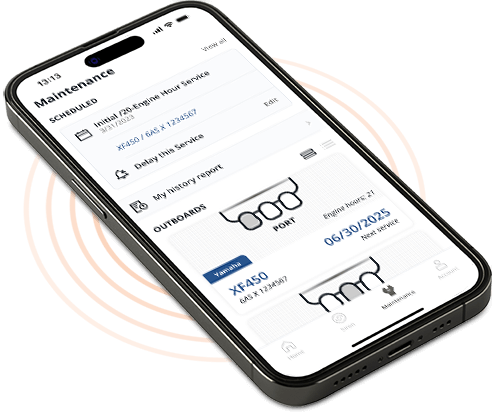

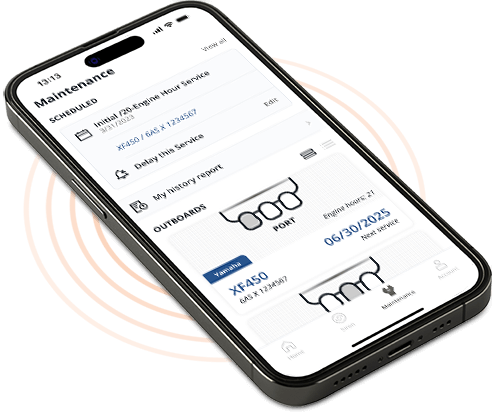

Know instantly with the Siren Connected Boat<sup>™</sup> App When was the last time you inspected your outboard for corrosion and flushed your engine? Stay on top of your maintenance with the Siren Connected Boat app. It tracks DIY and dealer-completed service right on your smartphone.

When was the last time you inspected your outboard for corrosion and flushed your engine? Stay on top of your maintenance with the Siren Connected Boat app. It tracks DIY and dealer-completed service right on your smartphone.