KEEP THE GEARS IN MOTION

The lower unit converts the power of your outboard’s engine to rotation of the prop shaft, which moves the propeller, which moves your boat. This hardworking device needs simple, regular maintenance. Let’s take a look at the lubricants and maintenance that go into keeping those gears in motion.

CHOOSE YAMALUBE

A superior anti-wear and anti-scoring performance additive and a dispersant inhibitor system help maintain seal pliability preventing leaks. Meets GL-4 and GL-5 requirements. Use whenever Mobilfluid 424 or Yamalube Friction Modified Shaft Drive Oil is specified.

Proper lubrication requires extreme resistance to pressure, foaming, and molecular shear. Since the lower unit operates underwater, its lubricant also has to be capable of maintaining lubricity should water leak inside. Always avoid automotive or tractor gear oils. Use a quality, marine-based formula, like Yamalube Marine Gearcase Lube or Marine Gearcase Lube HD.

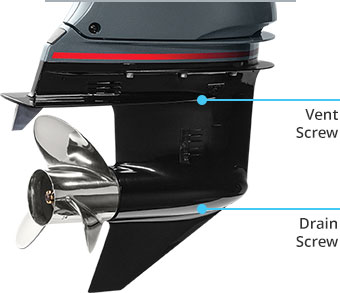

DO IT YOURSELF

NOTE: It’s best not to run the outboard right before checking the lower unit lubricant, as this will agitate the oil with whatever air is trapped inside. The resulting fine bubbles might be confused with the milky appearance that occurs with water ingestion.

NOTE: These drain screw crush washers are not reusable. They are a main source of protection against water intrusion into the lower unit, which can cause dilution of the lubricant. Use new sealing washers any time the drain or vent screws are removed. Do NOT try to save a few pennies here. Lower units are very expensive. It’s best to always have some extra drain plug gaskets on hand.

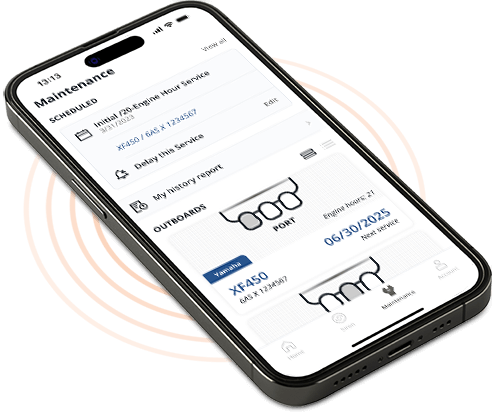

WHEN WERE THE LOWER GEARS LAST LUBRICATED?

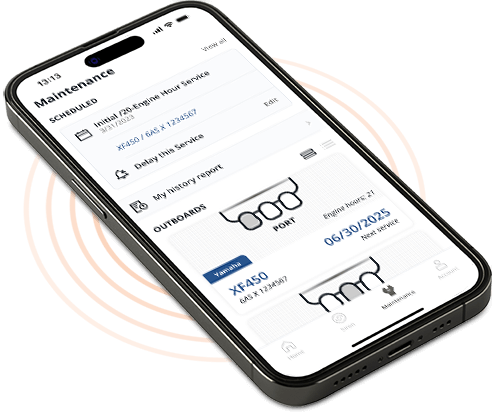

Know instantly with the Siren Connected Boat<sup>™</sup> App When was the last time your lower unit gear lube was changed or topped off? Stay on top of your service with the Siren Connected Boat app. It tracks DIY and dealer-completed maintenance right on your smartphone.

When was the last time your lower unit gear lube was changed or topped off? Stay on top of your service with the Siren Connected Boat app. It tracks DIY and dealer-completed maintenance right on your smartphone.